一种制备锂金属-无机固体电解质界面的超快工艺

An ultrafast process for the fabrication of a Li metal–inorganic solid electrolyte interface

Energy & Environmental Science ( IF 38.532 ) Pub Date : 2021-06-24 , DOI: 10.1039/d1ee00759a

Hirokazu Kitaura, Eiji Hosono, Haoshen Zhou

Abstract

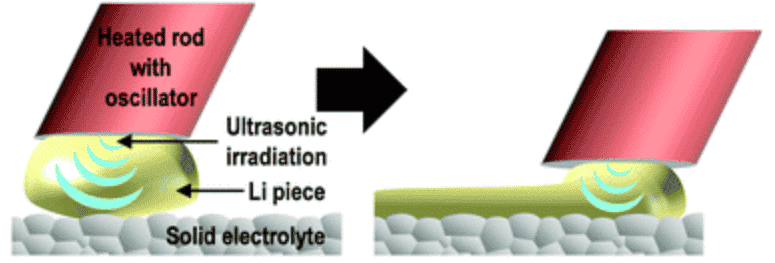

A lithium anode is expected to be applied to next-generation batteries using inorganic solid electrolytes (ISEs). When joining Li with ISEs, interfacial reactions often cause performance degradation and have been avoided. In this report, we demonstrate a new strategy for the ultrafast formation of a good interface between Li and ISEs, using a reactive process (ultrasonic-assisted fusion welding method). We found that ultrasonic irradiation helps in suitable interface formation between molten Li and ISEs, and the joining process finishes in just a few seconds. The obtained interface showed a low resistance and could be used under a high current density of 0.5 mA cm−2. The development of prototype cells for next-generation batteries was promoted by this ultrafast process.

Broader context

Li metal, which has a large theoretical capacity (3860 mA h g-1) and a negative potential (-3.04 V vs. standard hydrogen potential), is regarded as the ultimate anode material. All-solid-state batteries using inorganic solid electrolytes (ISEs) and Li metal are expected to be next-generation batteries with high safety and high energy density. Therefore, techniques to effectively bond Li metal to ISEs in a short time by a simple process are important in the research on Li–ISE batteries. However, the conventional methods require long and cumbersome processes. In this report, we demonstrate a new strategy for rapidly joining Li metal and an ISE using ultrasonic waves – the ultrasonic-assisted thermal fusion bonding method. We found that ultrasonic irradiation helps in the interface formation between Li and the ISE, and the joining process finishes in just a few seconds. The obtained interface showed a low resistance and could be used under a high current density. The development of prototype cells was promoted by this ultrafast process. This technology, which easily creates an electrochemically favourable Li–ISE interface, liberates people from the hassle of Li anode fabrication and will promote the realization of next-generation batteries and the utilization of electric vehicles.

一种制备锂金属-无机固体电解质界面的超快工艺

锂负极有望应用于使用无机固体电解质 (ISE) 的下一代电池。将 Li 与 ISE 结合时,界面反应通常会导致性能下降,因此已被避免。在本报告中,我们展示了一种使用反应过程(超声波辅助熔焊方法)在 Li 和 ISE 之间超快形成良好界面的新策略。我们发现超声波照射有助于在熔融锂和 ISE 之间形成合适的界面,并且接合过程只需几秒钟即可完成。获得的界面显示出低电阻并且可以在0.5 mA cm -2的高电流密度下使用。这种超快工艺促进了下一代电池原型电池的开发。

锂金属具有大的理论容量(3860 mA h g-1)和负电位(-3.04 V vs.标准氢电位),被认为是最终的负极材料。使用无机固体电解质(ISE)和金属锂的全固态电池有望成为具有高安全性和高能量密度的下一代电池。因此,通过简单的工艺在短时间内有效地将金属锂键合到 ISE 上的技术在 Li-ISE 电池的研究中非常重要。然而,传统方法需要漫长而繁琐的过程。在本报告中,我们展示了一种使用超声波快速连接锂金属和 ISE 的新策略——超声波辅助热熔合方法。我们发现超声波照射有助于熔融锂和 ISE 之间的界面形成,连接过程只需几秒钟即可完成。得到的界面显示出低电阻,可以在高电流密度下使用。这种超快工艺促进了原型电池的开发。该技术可轻松创建电化学有利的 Li-ISE 界面,将人们从制造锂负极的麻烦中解放出来,并将促进下一代电池的实现和电动汽车的应用。

注:中文翻译由计算机程序完成,请以原文为准。

来源:Energy & Environmental Science