Formulatrix USA Breaks Throughput Limits*

Tempest High Throughput Dispensers

TEMPEST Liquid Handler®

TEMPEST® is a non-contact multi-purpose dispenser. By utilizing 96 independently controlled outputs, it allows you to dispense up to 12 different reagents simultaneously. Dispense any volume, any reagent into any well.

- Precision - Non-contact microseptum technology uses positive displacement to ensure high precision control over a variety of reagent types including cells and magnetic beads.

- Low dead volume - non-recoverable dead volume down to 48 μL per chip

- Flexible - TEMPEST supports all SBS board types for easy integration with other robotic automation, and features optional board stackers and barcode readers.

- Fast - 200 nL to 96-well plates in as little as 3 seconds and 1 μL to 384-well plates in as little as 5 seconds

[System Introduction]

The TEMPEST® is a high-throughput, non-contact automated dispensing device with 96 independently controlled nozzles that can dispense any volume of up to 12 reagents into any well.

1、Product features

Modularity

High-throughput dispensing module can be connected to 12 different liquid chips at the same time, each chip dispensing by 8 nozzles together to complete (96 channels can be used at the same time, or can be split into 12 8-channel flexible use)

Efficient

The dead volume of the pipeline is only 40uL, and the dead volume using pipette tips is only 100uL

Fast

Add 200nL of liquid to a 96-well plate in 3 seconds and 1uL of liquid to a 384-well plate in 5 seconds

Flexible and versatile

TEMPEST can be matched to SBS plates with optional well stacking and sweep modules, and can be easily integrated with other automation workstations

Reliable

Non-contact micro septum technology with positive pressure drainage method maintains excellent dispensing accuracy and precision after millions of dispensing cycles

[Technical Advantages]

TEMPEST's core technology, the microfluidic chip, incorporates a set of microvalves to dispense a range of different volumes of liquid (0.2uL to mL) through positive pressure in conjunction with a microseptum. This set of microvalves contains two sets of volumes of septa, 200nL and 1uL, or 1uL and 5uL, with a compression frequency of up to 8 times per second. This patented technology enables precise dispensing of liquids of different viscosities.

Fast and high-throughput dispensing tasks -Most dispensing tasks can be completed in less than 40 seconds

384-well plates take only 5 seconds to add 1uL of liquid

384-well plates take 9 seconds to add 10uL of liquid 96-well plates take 3 seconds to add 200nL of liquid

384-well plates take only 13 seconds to add 20uL of liquid 96-well plates take only 4 seconds to add 5uL of liquid

384-well plates can be filled with 200nL of liquid in 6 seconds 1536-well plates can be filled with 200nL of liquid in 11 seconds

[System Specifications]

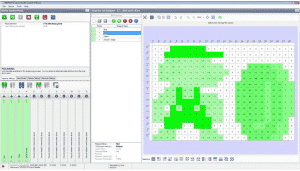

Software

The TEMPEST software provides an intuitive and user-friendly interactive interface that enables the design of complex fractionation processes in minutes. The software provides an intuitive visualization of dispensing design and hardware setup, as well as quick tools for gradient processing and inverse selection, and Excel table readout for advanced manual entry of separate dispensing volumes per well.

Chip Parameters

Formulatrix® offers a wide range of dispensing chips with various features, different flow rates and flow rates, and corrosion resistance levels. All chips are manufactured with certified molecular bio-grade materials to meet biomaterial compatibility and corrosion resistance.

Sweep Module

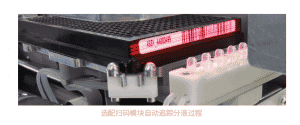

The optional sweep module allows dispensing based on the sweep record on the well plate. After scanning, the associated dispensing file is retrieved and executed

Orifice stacking module

TEMPEST can be matched to almost all SBS plates, including 24-well, 96-well, 384-well and 1536-well plates with optional sweep module for automatic tracking of the dispensing process. The optional plate stacking module can hold up to 24 SBS plates (based on 14.35mm plate height). The module is 350mm high and bi-directional, allowing the plates to be cycled from either side.

Specification parameters

L×W×H: 555mm×325mm×265mm, weight: 13.6 kg

Width: optional dump station up to 595mm

Depth: Optional tube carrier: 370mm

Height: 560mm for optional orifice stacking module

Related Applications

.png)

.png)

.png)

.png)