For Japan Toyo all-solid electrolyte*

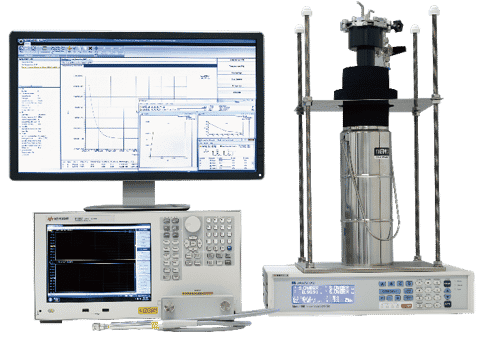

High frequency impedance measurement system

High Frequency Impedance Measurement System

4990EDMS-120K is suitable for high-frequency AC impedance testing of solid electrolytes, with an effective test frequency of up to 100MHz, for studying high conductivity materials, particle (grain) impedance and grain boundary (grain boundary) impedance of nano-materials, and various interface impedances.

- Wide temperature range from 80K to 473K

- High frequency characteristics at 100MHz

- Sealed/pressurized sample holders available

- Fully automated temperature variables and impedance measurements using dedicated control software

[System Introduction]

When a material needs to be industrialized, we must grasp most of its properties as widely as possible and with high precision, so as not to affect the direction of industrialization at a later stage due to wrong data and cause unnecessary losses.

4990EDMS-120K是东阳特克尼卡株式会社独自开发的(中国专利号:201780096021X),世界第一台面向全固态电池的高频阻抗测试系统。在达到100MHz的高频阻抗测试下,该系统可以将固态电解质的粒子和粒界阻抗进行分离。配合 -180℃ ~ +200℃的自动变温控制功能,该系统能够提供至今为止固态电解质活化能计算用高精度的内阻测量环境。

Since its launch, the test system has sold nearly 100 sets in Japan and has been approved by many top solid state electrolyte material research institutes in Japan.

[Technical Explanation]

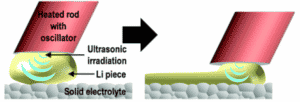

目前的锂离子二次电池(现LIB)使用有机电解质,存在“不耐热”、“担心漏液”等问题。以目前的LIB相关阻抗测量为例,下限为10mHz,上限为1MHz。另一方面,全固态LIB需要至少100MHz的上限频率,原因如下。

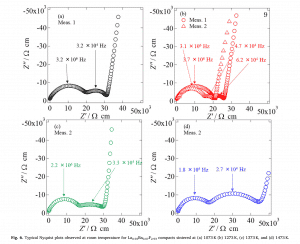

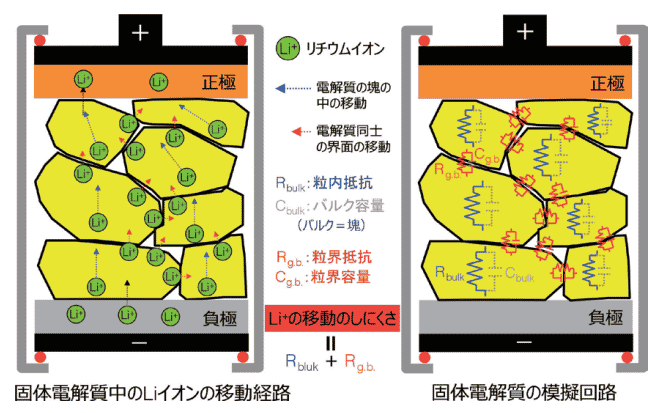

The performance of an all-solid-state LIB is strongly influenced by the transfer resistance value of lithium ions (Li+) in the solid-state electrolyte. For example, a solid electrolyte is formed by pressing a ceramic powder or by sintering it after pressing to create a solid electrolyte. Therefore, there are two paths of Li+ movement in a solid electrolyte: in the powder (intracrystalline) and at the powder-powder interface (grain boundaries), and the resistance to Li+ movement is the intracrystalline resistance component (Rbulk) and the grain boundaries. There are two components, the resistance component (Rg.b.) (see Figure 1). Capacitance is also formed at the grain boundaries (grain boundary capacitance: Cg.b.). In the development of solid electrolytes, the goal is to reduce the resistance to movement of Li+, but to achieve this, the resistance to movement of the solid electrolyte is divided into Rbulk and Rg.b. It is important to determine if it hinders). Cg.b. is too small to be detected in conventional measurements up to 1 MHz, and it is not possible to separate the two resistance components. Considering the size of Cg.b., the upper frequency needs to be at least 100 MHz and measurements need to be made over a wide frequency range from 10 mHz to 100 MHz.

Figure 1 Movement path of Li ions in solid electrolyte and simulation circuit

[System Specifications]

| Parameters | |

|---|---|

| Measurement frequency range | 20Hz ~ 100MHz |

| AC Voltage | 5 mVrms ~ 1Vrms |

| DC Voltage | ± 40 V |

| Compensation function | OPEN/ SHORT/ LOAD |

| Measurement Range | 25 mΩ ~ 40 MΩ |

| Variable temperature range | 80K ~ 473K |

| Sample Atmosphere | Helium, atmospheric or corresponding gas counterpart |

| Optional | Standard sample fixture |

| Sealed sample holder | |

| Pressurized sample holder | |

| Anti-overheating kit |

EDMS control software manufactured by Toyo Corporation

It controls CV measurements and impedance measurements, and supports complex test patterns.

| Measurement Technology | Scan Temperature (Step) <br>Scan Temperature (List) <br>Scan Bias <br>Scan Freq <br>Set Temperature (Single point) <br>Set Bias (Single point) <br>Meas / Sweep Bias Measurement <br>Meas / Sweep Freq Measurement <br>Meas / Scan Bias and Multiple Freq Measurement <br>Repeat <br>Wait |

| Temperature Controller | LakeShore 336 <br>LakeShore 335 <br>Rika Kogyo HA-900 |

| Data Storage | EDAT format (saved in csv format) <br>Z format (saved in ZView format) |

| ZView Link Features | ZView can display in real time |

| Communication Interface | GPIB-USB |

| Operating Environment | Windows 7 Professional Edition (64-bit) |

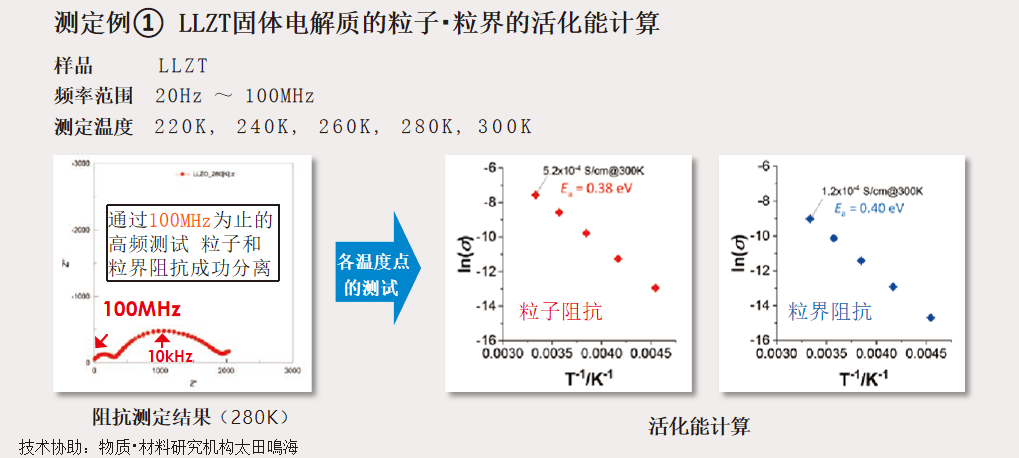

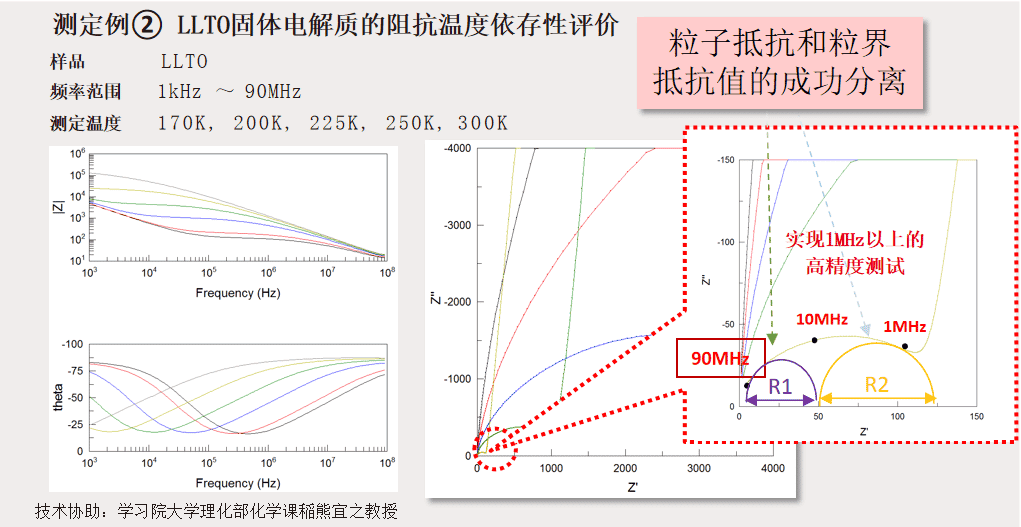

Arrhenius evaluation of particles and particle boundaries by variable temperature and high frequency impedance measurements

- For impedance testing of oxide or sulfide samples after powder pressing and sintering, the impedance of the sample can be ideally divided into three components: particle individual impedance, particle boundary (interparticle) impedance, and electrode interface impedance. In the case of activation energy characterization, Arrhenius curves can be obtained by measuring the impedance at each temperature point, but the impedance of highly mobile particles is very small, and it is not possible to obtain independent impedance spectra of particles and particle boundaries at frequencies of 1 MHz.

- This test system enables impedance testing up to 100MHz over a wide temperature range of 90K (-183°C) to 873K (600°C). This system enables the separation of impedance values of particles and particle boundaries of solid electrolytes and other materials and independent characterization.

Related Applications