FCE10 ferroelectric material test equipment

Japan Toyo Technica high frequency low noise ferroelectric evaluation system

Environmental concerns require the development of lead-free piezoelectric materials with performance comparable to that of Pb-based piezoelectric materials (PZT and related materials). Lead-based materials have been used in many applications such as actuators and sensors. Possible alternatives to Pb-based materials are (Bi,Na)TiO3, 4-11) (K,Na)NbO3, 12-15) and BaTiO3 16-18) and their solid solutions. Among them, (1-x)(Bi,Na)TiO3-xBaTiO3 (BNT-100xBT) and related materials have been intensively studied for their excellent electrical properties. BNT-100xBT ceramics in the MPB region (0.06 ⩽ x ⩽ 0.08), even though the Td in the MPB region is relatively low (110 °C-140 °C). Although the Tds for x < 0.05 (rhombohedral R3c, ∼150 °C) and 0.09 < x (tetragonal P4mm, ∼160 °C) are higher than the Tds in the MBP region, the Tds are still very low in practical applications. To overcome this problem in BNT-based ceramics, lattice distortion due to quenching has been reported to increase Td.

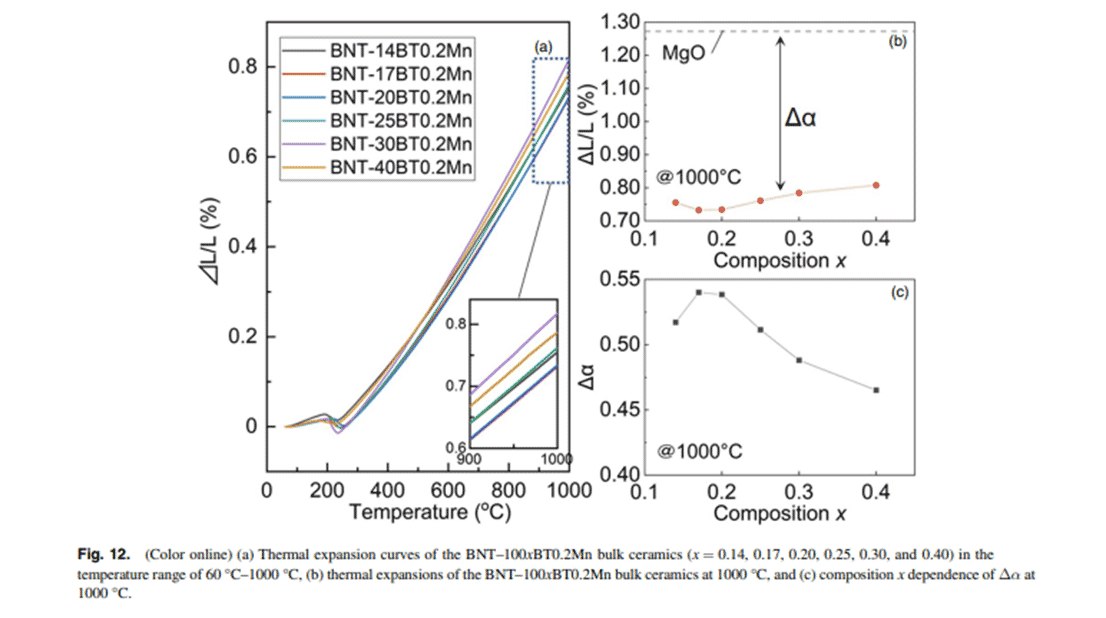

Electronic devices are manufactured using various film preparation techniques, such as spin coating and sputtering. Among them, screen printing is usually chosen for the fabrication of thick films because it is easy to form patterns and cost-effective for high volume production. Therefore, we have prepared lead-free BNT-100xBT (x = 0.03, 0.05, 0.07, 0.09 and 0.17) thick films using screen printing. In this study, we found that residual compressive stresses resulted in a higher Td in the BNT-100xBT thick films than in the thick films on MgO substrates or YSZ or Al2O3 substrates. the composition of the BNT-100xBT thick films was close to that of MPB (0.05 ⩽ x ⩽ 0.07) exhibits a large Pr of about 16 μC cm-2 at room temperature, while the increase in Td is limited because the thermal expansion of BNT-100xBT (0.05 ⩽ x ⩽ 0.07) is close to that of the MgO substrate. At x = 0.17 composition, the increase in Td (>100 °C) is greater than for thick films near the MPB composition (30 °C-70 °C) because of the large difference in their thermal expansion. However, the Pr of BNT-17BT thick films at room temperature is relatively low at 10 μC cm-2. Therefore, there is a need to improve the electrical properties of thick films at high Td at room temperature. The addition of Mn improves the electrical properties of BNT-100xBT and its related materials. However, the effect of Mn addition to BNT-100xBT thick films has not been demonstrated. In addition, the Td increase in BNT-100xBT thick films caused by residual compressive stresses around x = 0.17 and 0.17 < x is still unknown.

This study also investigated the effect of adding MnO2 to BNT-100xBT thick films ranging from room temperature to high temperature and the temperature dependence of BNT-100xBT (0.14 ⩽ x ⩽ 0.40) thick films to develop lead-free BNT-100xBT thick films with good electrical properties.

In this paper, the temperature dependence of (1-x)(Bi0.5Na0.5)TiO3-xBaTiO3 (BNT-100xBT, 0.14 ⩽ x ⩽ 0.40) thick films with MnO2 additive was investigated. The addition of 0.2 wt% MnO2 to the thick films increased the residual polarizability (Pr) and improved their temperature stability, with Pr values for thick films comparable to those of thick films with variable phase boundary (MPB) compositions and higher depolarization temperatures (Tds) than for bulk ceramics, with the highest Td of approximately 300 °C observed in the BNT-20BT thick films with MnO2 addition. To understand the variation of Td with composition x Td variation with composition x, we examined the thermal expansion of BNT-100xBT. © 2021 The Japanese Society of Applied Physics

Image 12 shows the crystalline phase of the sample characterized by X-ray diffraction (XRD) using Cu-Kα radiation (Rigaku Corporation Smart Lab). Thermal expansion curves from 60 °C to 1000 °C during heating of the bulk ceramics were measured using thermomechanical analysis (TMA; SII EXSTAR6000). Temperature dependence of dielectric constant and tanδ were measured during heating at 100 kHz using an impedance analyzer. P-E hysteresis was measured by applying a bipolar triangular waveform at 100 Hz using a ferroelectric test system (TOYO Corporation FCE10-S). The P-E hysteresis line is the average of cycles 2, 3 and 4 of the cyclic measurements.

Authors: Yuichi Sakai1 and Tomoaki Karaki

Institution: Toyama Industrial Technology Research and Development Center, Toyama 9300866, Japan 2 Department of Electrical and Electronic Engineering. Faculty of Engineering, Toyama Prefectural University, Imizu, Toyama 9390398, Japan

Published: Received June 1, 2021; revised July 4, 2021; accepted July 7, 2021; published online July 22, 2021

Key words: powder, lead-free piezoelectric material, high temperature, ceramic

Journal: Japanese Journal of Applied Physics

Article source website.Effect of MnO2 addition on temperature-dependent properties of tetragonal (Bi,Na)TiO3-BaTiO3 thick films prepared on MgO ceramic substrates substrates

Japan Toyo Technica high frequency low noise ferroelectric evaluation system