ECCS B310/B320 Electrochemical reaction visualization confocal system

Japan Lasertec Corporation Battery Electric

Introduction

With the development of next-generation energy storage devices, there is an increasing demand for high specific energy density, long cycle life, and high power density in lithium-ion batteries (LIBs). In recent years, compared with silicon (Si)-based anodes, SiOx anodes have attracted much attention due to their high reversible specific capacity of more than 1000 mAh g-1 and lower volume expansion, especially their long lifetime. However, as the SiOx particle size increases to the micrometer scale, their poorer electrical conductivity, volume expansion, and specific capacity decay become severe. In order to solve these problems, researchers have carried out a lot of fruitful work. For example, Liu et al. designed a Yolk@Shell SiOx/C microsphere with the advantages of volume change adaptation, high electrical conductivity and excellent structural stability. Liu et al. reported monodisperse SiOx/C microspheres with SiOx homogeneously dispersed in a carbon matrix, which can enhance the electronic conductivity of SiOx and buffer large volume changes. Nonetheless, these effective strategies for particle size reduction nanosize and creative unique structures are not suitable for the processing properties required in actual production. Therefore, with the requirement of high energy density batteries and the technological innovation of Mn-rich and high-Ni cathode materials, the development of micron-sized SiOx negative materials with long cycle life and good processing performance has become a top priority.

It is well known that TiO2 as an anode material undergoes a slight volume expansion ( 1.5 V). Therefore, titanium dioxide can serve as a good protective layer to improve the structural integrity of nano-sized Si/SiOx anodes. Previous studies have shown that thin coatings (~10 nm) of TiO2 or TiO2/C can be used for nanosized Si/SiOx particles. Recently, our group demonstrated that TiO2 can enhance the quality of the carbon coating on micrometer-scale SiOx, thereby improving the electrical conductivity of the electrode material. However, the volume expansion of micron-scale SiOx cannot be controlled by a simple thin TiO2 coating, and some space is needed to accommodate the volume expansion of micron-scale SiOx and a stronger coating to control the expansion domain.

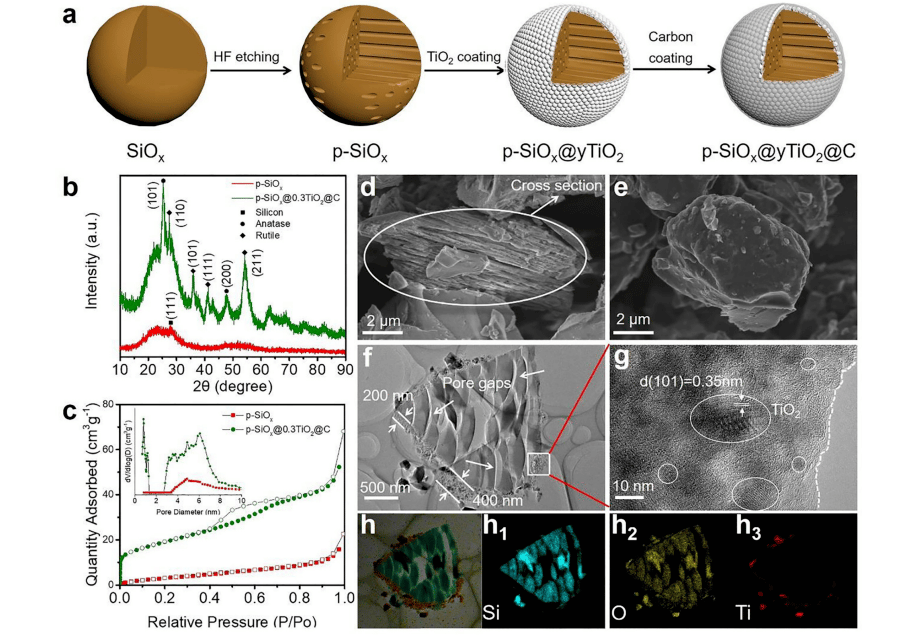

In this work, we designed micrometer-sized SiOx anode materials (p-SiOx@yTiO2@C) combining an internal void space and an ultra-thick TiO2/C hybrid coating (200-400 nm). Interestingly, TiO2 is not simply physically adsorbed on the micrometer-scale SiOx surface, but is chemically bonded to form Si-O-Ti bonds, which greatly reduces the interfacial resistance and improves the bonding of the coating to SiOx. The function of the thick TiO2/C hybridized coating can be well represented by visual observation of the thickness variation of the electrode material. This study provides a new concept for the development of micro-sized SiOx anode materials by combining void space and constructing thick hybridized coatings to achieve low volume expansion.

Applications

In this work, novel SiOx anode materials with low volume expansion and high ion/conductivity were designed by combining an internal buffer space and an external 200-400 nm ultra-thick TiO2/C hybrid shell. An electrochemical reaction visualization confocal system was initially developed to characterize electrode thickness changes, enabling real-time quantitative changes in electrode thickness during charging and discharging. Surprisingly, the maximum thickness expansion of the designed anode with a specific capacity of 1006.2 mA hg- was only 371 TP3T during the first lithiation process.Subsequently, the designed anode exhibited a stable cycle life, with the capacity after 100 cycles decaying by 7.831 TP3T compared to that of the 5th cycle.This suggests that the designed thick TiO2/C hybridized coatings are effective in reducing the swelling stresses of the micrometer scale SiOx expansion stress to the internal space. This work demonstrates that by rationally designing the surface hybridization coating and the block structure, the huge volume expansion of micron-sized SiOx particles can be controlled and a long lifetime can be maintained. This strategy paves the way for the development of micro-sized SiOx anode materials for high energy density lithium-ion batteries with long cycle life and good processability.

Picture 1 shows the real-time observation of the expansion changes of electrode materials during lithiation/delithiation using an electrochemical reaction visualization confocal system (ECCS, B310, Lasertec Co., Ltd.). The system consists of confocal optics, cell test equipment and two parts. electrode observation cell with a glass window (Fig. S1). First, the working electrode and the lithium foil as the counter electrode were prepared using a special tool and assembled into a special cell holder and fixed with screws. Then, 0.5 mL of electrolyte was added to the bottom of the cell body, and the cell holder was sealed to visualize the cell and the cross-section of the working electrode was kept against the glass window for observation. Finally, the cross-section of the visualized cell was inverted and left to stand for 12 h to allow full penetration of the electrolyte, and all the above operations were performed in a glove box.

Source

Authors: Fei Dou, Yuehua Weng, Guorong Chen, Liyi Shi, Hongjiang Liu, Dengsong Zhang

Institution: State Key Laboratory of Advanced Special Steel, School of Materials Science and Engineering, Research Center of Nano Science and Technology, Department of Chemistry, College of Sciences, Shanghai University, Shanghai 200444, China Department of Chemistry, College of Sciences, Shanghai University, Shanghai 200444, China

Published: Received 19 November 2019; Received in revised form 31 December 2019; Accepted 11 January 2020; Available online 13 January 2020

Keywords: lithium ion battery, SiOx anode, hybrid coating, cycle life

Article source website.Volume expansion restriction effects of thick TiO2/C hybrid coatings on micro-sized SiOx anode materials

Japan Lasertec Corporation Battery Electric